Displaying items by tag: WearCheck training

A well-trained workforce boosts profits

Profitability is generally good when productivity levels are high in most industries, and one of the long-recognised ways to ensure that productivity remains elevated is by upskilling the workforce through useful training courses.

As mechanised operations become increasingly complex, and the smooth running of components is increasingly critical to the general production and output in industry, so the need for ongoing employee education becomes more important.

We have run popular skills training courses for our customers for over 20 years. The training material assists staff in various positions within the maintenance teams to ensure that the monitoring and upkeep of components is conducted as efficiently as possible.

WearCheck employs reliability solutions services such as used oil analysis, thermal imaging, vibration monitoring, balancing, laser alignment and others, to monitor and maintain machinery at its optimum yield. Customers with well-trained maintenance staff can supply better samples and data to WearCheck, boosting the integrity of the test results and thus gaining optimum benefit from their condition monitoring programme.

WearCheck’s training courses cover accurate oil analysis report interpretation, correct sample taking, pre-planned maintenance schedules and good lubricant management.

Training courses are conducted around South Africa as well as in other regions where there are WearCheck customers. Courses are tailored and targeted at a range of levels within an operation, from factory floor to senior management.

Over the 40 years in business, WearCheck has compiled a database of sample diagnoses and wear trends, adding 600 000 new sample results annually to the data. Much of the training course material draws on this database, with the added benefit that WearCheck processes samples from a range of OEMs.

Oil Analysis One (two full days) costs R5 950.00. Oil Analysis Two (one full day) and costs R3 000.00. All courses include course material, refreshments, giveaways and certificates. Prices exclude VAT and are subject to change. Both of these courses can be presented at the customer’s venue, and courses can also be customised to specific customer requirements.

WearCheck also offers two more on-site courses:

• WearCheck Practical (in English or Zulu), (half day) costing R735.00 plus VAT per delegate

• WearCheck Customised – oil analysis for workshop technicians, (full day) costing R1 730.00 plus VAT per delegate.

All courses can be presented at the customer’s premises for a minimum of seven delegates. There may be an additional charge for the lecturer’s travel and accommodation, if needed.

Oil analysis training courses can also be arranged anywhere in the world. We conduct regular courses in Bloemfontein, Cape Town, Kimberley, Makopane, Nelspruit, Port Elizabeth, Rustenburg, Steelpoort, Botswana, Namibia, Tanzania (Mwanza), Zambia (Kitwe).

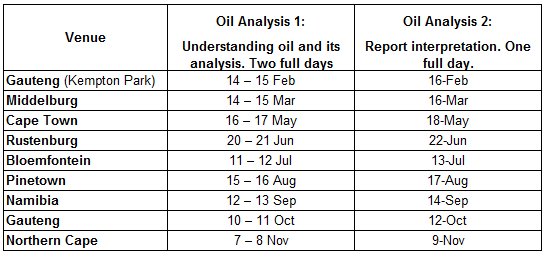

Our 2018 oil analysis training schedule is as follows. Remember - reservations are essential as courses fill up quickly.

2018 WearCheck Training Courses

|

Venue |

Oil Analysis 1: Understanding oil and its analysis |

Oil Analysis 2: Report interpretation |

|

|

Two full days |

One full day |

|

Gauteng |

13-14 February |

15 February |

|

Middelburg |

13-14 March |

15 March |

|

Cape Town |

15-16 May |

17 May |

|

Rustenburg |

19-20 June |

21 June |

|

Bloemfontein |

10-11 July |

12 July |

|

Pinetown |

14-15 August |

16 August |

|

Namibia |

11-12 September |

13 September |

|

Gauteng |

16-17 October |

18 October |

|

Northern Cape |

6-7 November |

8 November |

For more details on course content, view Training at www.wearcheck.co.za. To book, phone Steven Lumley on (031) 700-5460 or email This email address is being protected from spambots. You need JavaScript enabled to view it..

Mobius training for reliability solutions

As the certified Mobius training centre for the entire African continent, WearCheck runs Mobius courses on request from customers, on-site at the customer’s premises, anywhere in Africa (apart from SA, DRC and Kenya).

The full Mobius course includes compulsory six month practical training sessions. Participants are guided by WearCheck expertise that has been gained through the successful implementation of condition monitoring programmes tailored to meet the specific needs of operating, engineering and maintenance departments across a range of industries. Through these practical sessions, the skills of the technicians are developed in order to progress to the next level.

The Mobius Institute is a worldwide provider of education in reliability improvement, condition monitoring and precision maintenance, to industrial plant managers, reliability engineers and condition monitoring technicians.

The Mobius Institute Board of Certification (MIBoC) is ISO/IEC 17024 and ISO 18436 accredited, providing globally-recognised certification to category I-IV vibration analysts in accordance with ISO 18436-1 and 18436-2.

Mobius courses are run by WearCheck anywhere, any date, on demand.

- One day vibration analysis awareness: R 6 370 per delegate (group rates and on-site training days available on request)

- Two day laser alignment: R10 595

- Two day balancing: R10 595

- Three day CAT I: R15 000 (excl. exam)

- CAT I exam R4 134

- Four day CAT II: R18 000

- CAT II exam R4 941

- Four day Cat III: R22 000

- CAT III exam R5 751

- Five day CAT IV: TBA

*prices exclude VAT, and are valid until the end of 2018.

Note: a minimum of six candidates is required for all training courses. There may be an additional charge for the lecturer’s accommodation and travel.

To book a Mobius training course, please contact Christene on This email address is being protected from spambots. You need JavaScript enabled to view it. or Dennis Swanepoel on This email address is being protected from spambots. You need JavaScript enabled to view it. or call WearCheck Johannesburg on (011) 392-6322.

Click here to download our Mobius Training Schedules for 2018

Renewable energy

WearCheck recently conducted training courses for wind turbine manufacturers Nordex and Acciona at Cape Town’s SARATEC (South African Renewable Energy Centre) institution, focusing on wind energy and sustainable resources and how to maintain the equipment that harnesses these resources in peak operating condition.

SARATEC is the first national renewable energy technology centre in SA to offer specialised industry-related training for the entire renewable energy industry, and served as a venue for the WearCheck training courses.

Pictured during wind turbine training at SARATEC are Steven Lumley (third from left) then Philip Schutte on her left and Ian Gray (far right). With them are some of the students who completed the course - Kunene Nhlakanipho, Noel De Rose and Elton White from Acciona.

A first for WearCheck

Dennis Swanepoel of WearCheck’s reliability solutions division has just made history when he became the very first Master Vibration Analyst in South Africa after he met all certification requirements, and also passed his CAT IV exam recently held through the Mobius Institute in South Africa - with flying colours, to boot.

As a Master Vibration Analyst, Dennis is qualified to lead condition monitoring teams, and has deep insight into the dynamics and failure modes of machines. He can design tests to solve complicated problems, and no rotating machine problem is too difficult for him to solve. In short, with his qualification, Dennis carries the highest regard in the field of machine condition monitoring.

The Mobius Cat IV course covered advanced measurement signal processing techniques, torsional vibration and cross-channel measurements, dynamics including mass/stiffness/damping and natural frequencies, modal analysis and operating deflection shapes, orbit and centreline analysis, rotor dynamics, correction techniques including isolation, damping, and tuned absorbers, and other advanced topics.

Dennis, you have done WearCheck proud… huge congratulations, we are extremely proud of you!

WearCheck runs a wide selection of training courses. For more info and a training timetable, please click here

WearCheck Training. Africa & Beyond.

Ghana, Zimbabwe

WearCheck training manager Ashley Mayer conducts oil analysis courses for South African customers as well as those in exotic locations. Recently, he travelled to West Africa and Zimbabwe to offer training courses.

Ashley Mayer (front row under banner, blue shirt) is seen with African Mining Services delegates who attended an oil analysis course at a mine site in Zimbabwe recently.

Workers from AngloGold’s Ashanti site at Iduapriem in Ghana listen attentively to WearCheck training manager Ashley Mayer.

Abu Dhabi, Dubai

Steven Lumley, WearCheck technical manager, travelled to the Middle East to attend a conference and to run some training courses for customers in the region. She conducted a training course for employees of the NDC (National Drilling Corporation) of Abu Dhabi, and a course for Al Shirawi employees in Dubai.

Steven Lumley talks delegates through water contamination and oil analysis in Abu Dhabi recently.

Steven Lumley conducted oil analysis training for delegates of Al Shirawi in Dubai recently. She is pictured here (third from right) with some of her students.

Train for Productivity

As oil analysis and reliability solutions are increasingly complex fields which are constantly evolving with new technology, WearCheck offers a variety of training courses for several levels of staff, targeted at workers in the maintenance and management arenas.

WEARCHECK 2017 OIL ANALYSIS TRAINING COURSES

Efficiency, speed and reducing the need to redo tasks – these are just some of excellent returns on investment for businesses that train their employees to do their jobs competently.

This is reinforced through the words of management guru Peter Drucker, ‘If you think training is expensive, try ignorance.’

Oil Analysis One covers two full days and costs R5 540. Oil Analysis Two and the NetCheck course cover one full day each and each costs R2 795.

Courses include course material, lunch, refreshments, giveaways and certificates. Prices exclude VAT and are subject to change. All courses can also be presented at the customer’s premises for a minimum of six delegates.

Other on-site courses: WearCheck Practical (in English or Zulu), a half day course costing R650 plus VAT per delegate, and WearCheck Customised – oil analysis for workshop technicians, a full day course costing R1 525 plus VAT per delegate.

For on-site training, there may be an additional charge for the lecturer’s travel and accommodation, if needed.

Training courses can be arranged anywhere.

For more details on course content, view Training at www.wearcheck.co.za. For bookings phone Kay Meyrick on (031) 700-5460 or email This email address is being protected from spambots. You need JavaScript enabled to view it..

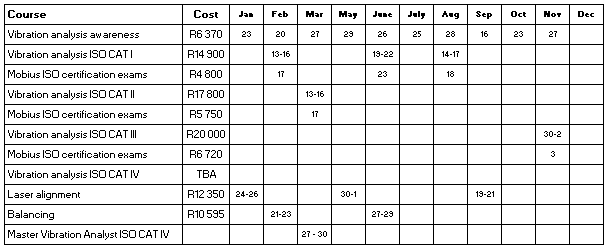

RELIABILITY SOLUTIONS TRAINING COURSES

Mobius training is offered in 153 countries, and is recognised the world over as the preferred standard for reliability solutions technicians. Mobius courses are run by WearCheck and presented either on-site or at the ABB School of Maintenance premises.

Courses include Alignment, Balancing, Awareness, and CAT I to III, and costs (excl VAT) are as follows, when presented at the ABB venue at 2 Lake Road, Longmeadow Business Park, Modderfontein, Johannesburg, South Africa.:

Courses can be presented on-site, and will be quoted accordingly

To book any of the above courses, or get course dates for the second half of 2017, please contact Dennis Swanepoel on 082 878-1578 or email This email address is being protected from spambots. You need JavaScript enabled to view it., or contact Christene Fourie on (011) 392-6322 or email This email address is being protected from spambots. You need JavaScript enabled to view it.