In part 1 we dealt with the physical properties of oil, we will now discuss the chemicals that are added to the base stock in order for the oil to do its specific job? In other words, if I buy a can of oil, how good is it?

The most important thing to realise at this point is that if you buy oil from any reputable oil company there is no such thing as a ‘bad oil’. You can certainly get cheap oil and you can pay up to R200 a litre if you really want to; you get what you pay for but there are no ‘bad oils’.

So, how do you know how much bang you are getting for your buck? Engine oils (and to a lesser extent, gear oils) are graded according to performance specifications. There are any number of international bodies that are equipped and certified to carry out testing to confirm whether a certain product meets internationally accepted performance criteria. The one that most people are familiar with is the API or American Petroleum Institute although Europe has the European Automobile Manufacturers’ Association, and in Japan it is JAMO; even our own South African Bureau of Standards (SABS) has specifications for lubricants. In this article, we will only look at the API which grew out of the United States military classification system.

Systems such as the API came into being when engine manufacturers started communicating their needs to the oil companies.

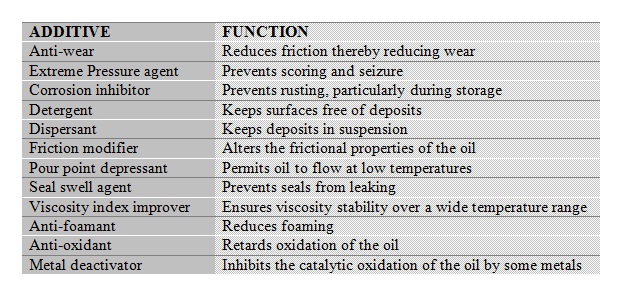

When an engine oil is blended, many chemicals (additives) are added to the oil. These additives impart certain properties to the oils enabling them to function in a desired manner. Below is a list of some typical additives and their functions:

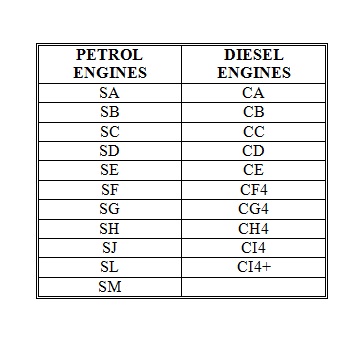

The right combination of the right additives in the right amount are blended with a refined crude oil (base stock) in order for an oil to do its job. The API grades these oils on how well they can do that job. Most API specifications are of the format Sx/Cy where x and y are letters of the alphabet; the first half of the designation refers to petrol engines and the second half to diesel engines. The full range is shown below:

The “S” designates petrol engines and stands for spark as these are spark ignition engines; the “C” stands for compression as diesel engines employ compression ignition. Basically, the further you go into the alphabet, the ‘better’ the oil is. What this actually means is that an SM oil has passed a greater variety and more stringent performance tests than an SG oil.

Most engine oils will generally meet both an S and a C classification, for example SL/CF4. The diesel specification is usually lower as the combustion of diesel puts much higher demands on the lubricant; the combustion by-products of diesel are much more aggressive than for petrol.

In order to grade engine lubricants, engine manufacturers have designed a series of tests to be carried out under scientifically controlled conditions. Most major engine manufacturers are involved and, in order for an oil to achieve an API specification, all tests must be passed to the level stipulated by the manufacturers.

These performance tests do not look at overall performance, but specific characteristics of the oil under test. For example, the Caterpillar IG2 test is used to determine the ability of the oil to protect against ring sticking, wear and accumulation of deposits under high speed turbo-charged conditions. The Peugeot TU3 test is used to measure the ability of the oil to protect against valve train scuffing.

All tests are defined by the American Society for Testing and Materials (ASTM International) which works closely with the API and the SAE. The SAE defines the need for a new specification (in conjunction with oil companies and additive manufacturers), the ASTM develops the tests and the API defines the new oil category. This is a very lengthy, complicated and consultative process, as all stakeholders need to be involved.

This explains why a simple oil analysis laboratory cannot determine if an oil meets a particular specification or not. Chemical and physical tests cannot replace actual performance testing; the costs to an oil company trying to get a new product certified runs into millions of dollars.

Whether a product meets a specification or not is actually an act of faith as it is not within the means (in terms of cost or facilities) of the man in the street to have it checked.

Oil base stock and a selection of additives.

The gear oils are graded in a similar way by the API. These oils will have what is known as a GL rating, with “GL” standing for “gear lubricant”. The GL rating measures the level and effectiveness of the EP (Extreme Pressure) additive in the oil. EP additives prevent scoring and scuffing of gears under high load applications.

The scale runs from GL1 to GL6 (although GL6 has been technically obsolete for many years), GL1 having the lowest EP level and GL6 the highest. Oils typically found in automotive applications are GL4 and GL5. GL4 oils would normally be used in a manual gearbox application and GL5s in the differential.

The GL4 designation became obsolete in 2010.

As environmental legislation puts heavier and heavier demands on engine manufacturers, the engine manufacturers are putting heavier and heavier demands on the lubricants. Rather than put the muck in the atmosphere, let’s put it in the oil; engine oils work very much harder than they did 10 years ago.

One group of oils that hasn’t been discussed yet needs to be touched on briefly - synthetic lubricants.

Crude oil is removed from the ground, refined and then additives are blended to produce the finished product. The refining process removes undesirable entities from the crude oil until a finished product is arrived at which will do the job. This does not remove all the nasties, merely the ones we really cannot live with.

A synthetic oil is a base stock that has been designed, in a laboratory, with all the desired properties and none of the undesirables. This makes synthetic lubricants vastly superior to mineral ones, however, there is a cost involved. Synthetic oils are very good but they are very expensive.

So, we have dealt with the physical and chemical properties of oils and their performance specification but how does the stuff actually work?.

More to follow in part 3.