Condition Monitoring

Condition Monitoring Services

|

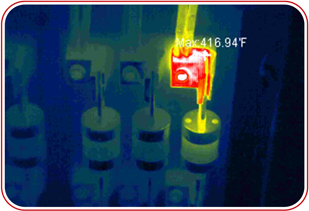

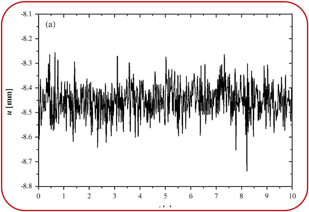

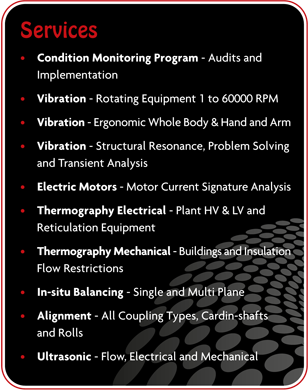

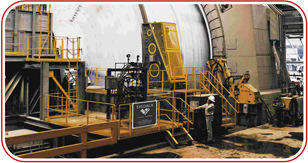

The addition of a whole new dimension to traditional predictive maintenance services has transformed WearCheck into a complete one-stop condition monitoring destination, offering a highly sophisticated world-class range of tests over and above the original oil and fuel analysis services. The new Reliability Services division conducts scientific vibration and thermography analysis and a host of related tests methods such as structural resonance, ultrasonic services and more - highly specialised technology that helps boost the lifespan of machinery and keep it operating at optimum levels. The comprehensive package of maintenance options now presents a complete reliability solution for the mining, earthmoving, industrial, transport, shipping, aviation and electrical industries. Plant asset optimisationCondition monitoring forms the basis of a well-established Condition Base Maintenance program, forming an integral part of plant asset optimisation. This not only increases profit, but plant availability too, by reducing unplanned downtime and catastrophic failure of rotating components on plant assets. It is therefore highly beneficial to know the health and the condition of both machine and plant, through effective measuring and monitoring. The condition monitoring team consists of experienced and well-trained personnel, trained in the various technologies and with the ability to perform special investigation on machines, plant equipment and their structures using specialised techniques such as Operational Deflection Shape (ODS), transient analysis and resonances tests. The tests are geared to ensure that assets reach their anticipated life expectancy and beyond, and increase their reliability by performing pro-active services such as laser-alignment, in-situ balancing and gear profiling on both pinion and girth gears of large or small mills, to reduce unacceptable forces and vibration levels. Key among WearCheck's strengths is our trade knowledge, as well as our experience gained from a diverse customer database that covers all machinery and all industries in Southern Africa and beyond. Our expertise is not limited to specific plants, machines or processes. WearCheck recently acquired the Condition Monitoring division of South African engineering company ABB, effectively adding a team of 16 highly experienced technicians to the newly-formed reliability solutions division, and adding significantly to our capability in this field. VibrationWhere needed, vibration analysis is performed and corrective action reports generated, with recommendation on all machines (not only the ones where problems are detected), to reduce vibration levels based on predefined international standards, as agreed by plant engineers. Customers can further increase plant reliability by adopting a pro-active approach after any maintenance intervention - such as the performance of in-situ balancing, shaft centre alignment or structural resonance tests. This effectively minimises external forces and unacceptable vibration levels of rotating parts and components. TribologyThe concept of analysing oil samples from a machine or component is similar to that of taking a blood sample from a person - the results determine the health status of the unit. WearCheck's highly-skilled diagnostic team then analyses the results and recommends how to rectify any abnormal findings. WearCheck's oil and fluid analysis programmes consist of analysis for wear, level of contamination and the condition of the oil found in any oil-wetted compartment or oil filter equipment, ranging from earthmoving units, transport fleets and processing plants to ships and aircrafts. ThermographyThermography is a non-intrusive technology that allows potential problems - such as electrical, mechanical or flow restrictions - to be 'seen' on a thermal imaging diagram. The potentially problematic surfaces emit radiant heat which is displayed in different colours, indicating abnormal temperature and fluctuations. This can be performed 'at a glance' using digital overlaying of the thermal image - a process also known as fusion. Additional servicesBalancing |

|

Using Video Amplification (VA) in Condition Monitoring

For more information on Reliability Solution products and services please contact:

Philip Schutte

Reliability Solutions Manager

C: +27 (0) 76 982 9774

E: This email address is being protected from spambots. You need JavaScript enabled to view it.